Milk Standardization: A Brief History Lesson

What is milk standardization? This question, now seemingly obvious to those of us in the industry, has not always been so. In November of 1917, L. L. Van Slyke, in an article published in the Journal of Dairy Science entitled “The Standardization of Market Milk” – which was one of the first scholarly articles on the then new trend of milk standardization— discusses the subject in what to us must seem an entertaining manner. While his interrogation of the subject may seem elementary to us now, to him it was of the utmost importance. Taking a look at his originary view of the subject might also be very valuable for us as it might refresh the way we see the subject and possibly help us generate new thoughts about it. He begins his discussion thus:

“What do we mean by the standardization of milk? Or, perhaps, it is better to put the question in this form: “What do we mean by standardized milk?” We get no help from the dictionary. What kind of a standard have we in mind? Is it a sanitary standard, covering the number of bacteria in milk, the amount of dirt, acidity, etc.? Or is it a standard of composition based on fat and solids? Or is it something else?

It becomes obvious at once that the expression “standardized milk” does not carry its meaning on its face. As a matter of fact, there is no generally recognized, authentic definition.

Another expression is in common use, synonymous with standardized milk, and that is “adjusted milk.” It is therefore desirable to incorporate these two terms in our definition:

Standardized milk or adjusted milk is milk in which the original fat content has been changed, and also the ratio of fat to the other milk solids, by the removal of milk-fat, or by the addition of skim-milk, or by the addition of cream.”

While the technology we use to standardize milk has continuously gotten more complex and precise, not much has conceptually changed in the last one hundred plus years.

An Overview

Standardization of milk is essential to the dairy sector. It guarantees that the milk produced and supplied to consumers complies with specific quality and safety requirements, which enhances the industry’s reputation as a whole. The significance of milk standardization in the dairy business and its effects on customers, producers, and the sector as large will be discussed in this article.

Let’s start by defining milk standardization. When milk is standardized, its composition is changed to conform to a pre-determined set of requirements. These requirements may change based on differing state requirements as well as specific recipes that different dairies may have. Basically, standardization is the process of separating and then adjusting the different component nutrients of milk. These components are fat, protein, solids non-fat, and total solids. While non-standardized milk is distributed directly to consumers from the farm, standardized milk is often sold in supermarkets and other retail

Standardization starts with separation. Before standardization can take place, the cream and milk must be separated from one another on a dairy line before the standardizing process can begin. After separation, the two elements— cream and milk— are then combined once more. However, not all of the original fat content is restored; only the quantity required for milk to be categorized as skimmed, semi-skimmed, or whole is restored (or the required amount of fat for different cream products).

When using milk as an ingredient in yogurt, cheese, and other products, the same technique is utilized to obtain the precise fat content required. When creating different goods, standardization can also refer to the ‘re-adding’ of protein content in precise quantities as needed.

In short, milk standardization is a highly advantageous aspect of the dairy industry that makes it what it is today. The industry’s reputation is enhanced when milk is standardized since it is seen as being of higher quality.

Standardization Requirements for Different Sectors of the Dairy Industry

Milk components are measured in native milk and nearly all derivative milk-based products. This includes raw milk, processed milk, homogenized milk, cream, whey, cheese milk, yogurt and ice cream mix. Components can be measured when the product is in liquid form and, in some cases, when it is in a finished semi-soft condition like cheese and yogurt. This paper focuses primarily on the liquid analysis of dairy products. Typical components measured include fat, protein, lactose and solids.

Milk Production

Milk used for drinking is referred to as fluid milk in the dairy industry. Fluid milk is legally required to have specific levels of butterfat. Non-fat milk (skim) is typically less than 0.10% butterfat. Low fat milks include 1% and 2%. Whole milk is 3.25% (3.5% in California). Producers must test their milk to ensure that they are meeting the fat requirements for the product that they are making. The state of California adds an additional requirement for fluid milk solids non-fat of 9.0% for skim milk, 11.0% for 1% milk, 10.0% for 2% milk and 8.7% for whole milk.

Cheese Production

Cheese manufacturers measure protein and fat. Most of the protein is casein, about 78% in bovine milk. In the production of cheese, the ratio of casein to fat is a critical indicator of cheese yield and quality. Different types of cheeses have different casein to fat (C/F) ratios. Cheddar has a C/F ratio of 0.70 while Swiss has a 0.85, Parmesan a 1.10, Havarti a 0.60 and Low Moisture Part Skim Mozzarella has a 1.10 C/F ratio. Measurement of the fat and protein in every cheese vat is a key requirement for most cheese producers.

Ice Cream and Yogurt Production

Ice cream and yogurt manufacturers need to know their fat and total solids values on a per batch basis. Ice cream typically has between 10% to 16% butterfat. Many producers also require knowledge of the fat and solids values in their cream. Cream is typically targeted at 40% butterfat.

A Look Forward

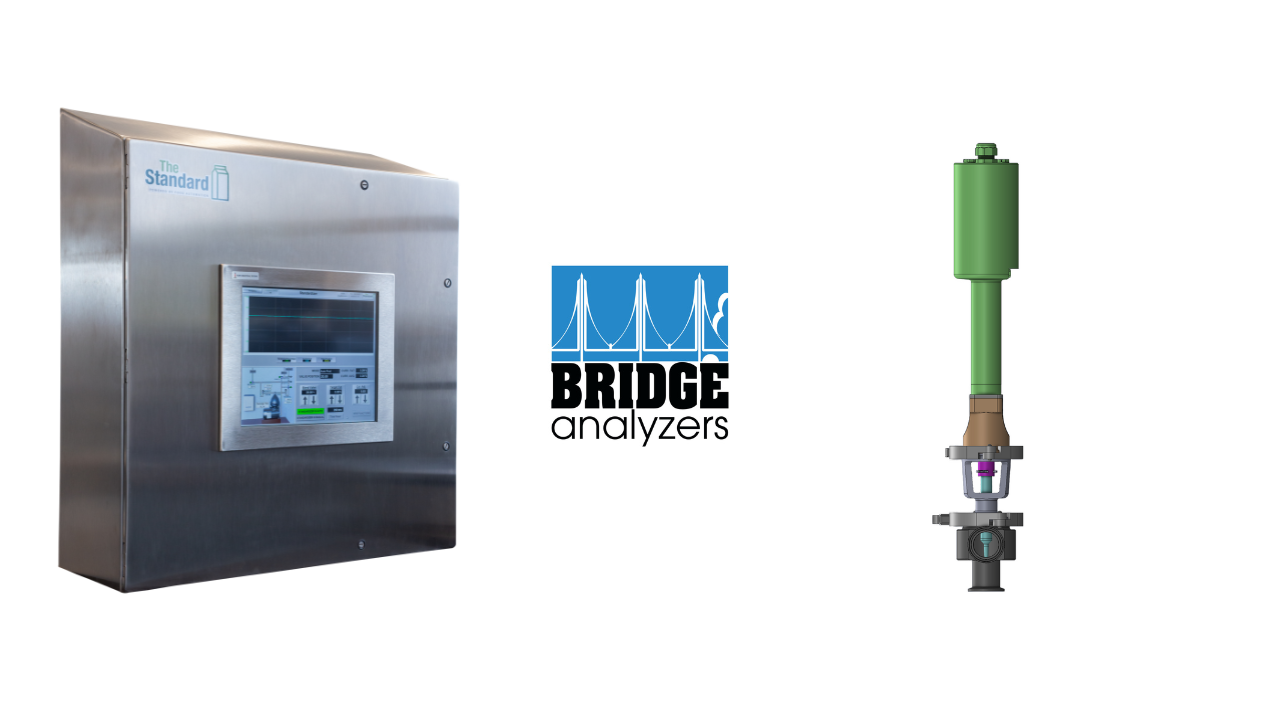

The Standard is Driven by The Digital Throttling Valve from Bridge Analyzers

The Standard is a groundbreaking new milk standardizer from long time dairy process expert, Craig Nelson of Food Automation. The Standard provides full integration with any and all surrounding equipment that may influence accurate blending. This includes pasteurizers, product selections, raw material labs, final product bench labs, separation, flows, pressures, and destination routing. All these factors influence the inline blending results and are considered in The Standard’s algorithms. Integration can either be hardwired or networked.

The Standard saves its results and continually learns to accurately set blending equipment to create the best product possible. Factors like seasonal changes to raw materials or milk components and the effects of the surrounding process are recorded, and the system gets better each day at starting or holding the blending valves. No more wobbling after every separator de-sludge or making bad product until the system’s control gets settled in.

The Standard is driven by the Bridge Analyzers Digital Throttling Valve. The 3A-approved Digital Throttling Valve delivers the most precise blending in the dairy industry. The Standard will soon have these The Digital Throttling Valve from Bridge Analyzers – which are fully compatible with ControlLogix Ethernet for ease of replacement— integrated into them. The Standard is built using Rockwell automation’s ControlLogix. This provides ease of integration in the majority of process manufacturing applications. For dairy applications, The Standard uses Quadbeam sensors with very specific light wavelengths. This means your product will be within +/- 0.030s accuracy or better.